... Bringing Value to our Customers

... Bringing Value to our Customers

... Bringing Value to our Customers

P: 260-627-0030

F: 260-627-0080

P: 260-627-0030

F: 260-627-0080

Compression Molded Products

From small scale and prototyping to large scale production runs, we manufacture a variety of products utilizing compression molding and other techniques to meet your specifications.

Production Capabilities

Our design & production teams have the knowledge necessary to assist each customer in obtaining the desired end product. We use electronic data, molds and secondary tooling along with in-process gauging to make sure each part is manufactured to customer satisfaction. Quality is of primary importance with high-priority placed on taking steps to ensure consistency and accuracy on every shipment. Lean manufacturing and continuous improvement are used to reduce waste, hold down cost, increase quality and meet timely delivery schedules.

Equipment Capabilities

.

Our molding equipment line-up includes 15 compression molding presses ranging from 400 to 4400 tons.

Our press bed sizes range from 42" x 67" up to 144" x 144".

Added to this are three infra-red ovens used for GMT processing.

Industries Served

|

|

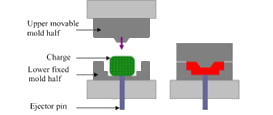

Compression Molding

Using compression molding techniques, we produce parts using fiberglass reinforced or other composite materials to produce parts with high mechanical strength. Choosing thermoset or thermoplastic materials we produce the part to meet your unique application.

Material options include:

- BMC (Bulk molding compound) glass filled

- SMC (Sheet molding compound) from 12% to 48% glass filled

- GMT in 20% to 40% glass filled PP with UV stable material available

- Zeon - BMC Kevlar/ Ceramic fill

- ABS

- Epoxy Vinyl Ester resins

- Urethane resins

- Bio resins (Corn and soy based)

- PLA (Polylactic acid biodegradable resin)

- Polylactic Acid - Biodegradable resin)

Large Capacity

With one of the largest presses in the US we can produce your large part in one piece. We have the tonnage capability for specialized applications.

Our large press bed measures 144" x 144" and provides 4400 tons of clamping force. We are one of only a few in the entire US with this capability.

SMC Manufacturing

SMC or Sheet Molding Compound manufacturing is a process whereby we are able to produce your part with a superior finish and high structural integrity.

Automotive & Heavy Truck

We produce automotive and heavy truck parts utilizing composite materials. We also specialize in using dual composite material types in one mold to give different sections of your part unique structural qualities.

About

R3 Composites is a family owned business committed to providing quality products at competitive prices.

When you choose R3 Composites, you are getting more than a parts vendor - you are choosing a manufacturing partner. We add value to the relationship by working with you every step of the way to make sure that every part meets or exceeds quality standards. This gives you confidence that your end product will consistently meet your expectations.

The Carver family has also expanded into manufacturing operations at Carver Non-Woven Technologies. Here we make non-wovens with new state of the art industry processes. This enables us to create breakthrough materials with superior engineering qualities, including our own Carver Technilite.

Call our sales team to learn more.

Contact

R3 Composites, Inc:

14123 Roth Rd

Grabill, IN 46741

Phone: 260-627-0030

Fax: 260-627-0080

Carver Non-Woven Technologies:

706 E Depot St

Fremont, IN 46737

Phone: 260-627-0033

Fax: 260-627-0043

Website: www.carvernonwoven.com